Dinar

Pretražite sajt Zatvorite

- Moj nalogMoj nalog Zatvorite

- Lista za upoređivanje

- Lista želja (0)

Korpa Zatvorite

Nemate artikle u vašoj korpi.

Sve Kategorije

Opcije Zatvorite

- Step motori

- Servo motori

- DC Motori bez četkica

- Obradni motori

- Linearna mehanika

- Transmisija

- Elektrika

- Elektronika

- Podmazivanje i Hlađenje

- Ostalo

- Kontakt

- Sve Kategorije

- Nazad

- Step motori

- Servo motori

- DC Motori bez četkica

- Obradni motori

- Linearna mehanika

- Nazad

- Kuglična navojna vretena

- Trapezna navojna vretena

- Oslonci za kuglična navojna vretena

- Kućišta za kuglične navojne matice

- Profilisane šine sa kolicima

- Vođice sa kolicima sa točkićima SG

- Vođice sa osloncem SBR

- Rasečeni ležajevi sa kućištem SBR

- Vođice

- Linearni ležajevi sa kućištem SC SCS

- Linearni ležajevi

- Ležajevi u kućištu KP i KFL

- Oslonci za vođice

- Nosači kablova

- Zaštitne harmonike

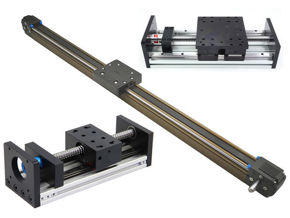

- Gotovi sklopovi linearnog vođenja

- Točkići

- Transmisija

- Elektrika

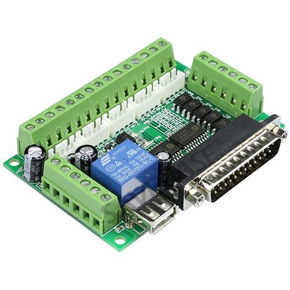

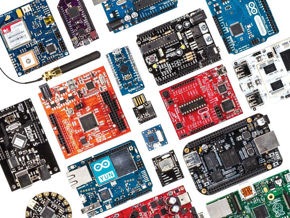

- Elektronika

- Podmazivanje i Hlađenje

- Ostalo

- Kontakt

Newsletter

Wait...

Informacije

Servisi za klijente

Copyright © 2026 Mehatron.rs. Sva prava zadržana.