JKD2060AC is a new generation digital 2- phase stepper motor driver, based on a 32-bit DSP processor, combination of the anti-resonance, low noise, micro-step and low temperature rise technology significantly improve the performance of the stepper

motor, has low noise, small vibration, low temperature rise and high-speed torque.

The driver use online adaptive PID technology, without manual adjustment can be automatically generated optimal parameters for different motors, and achieve the best performance.

Supply voltage range from 20VAC to 60VAC or from 24VDC to 80VDC, suitable for driving various 2-phase hybrid stepping motors which phase current below 7.2A.

The microstep can be set from full step to 51200steps/rev and the output current can be set

form 2.4A to 7.2A; with automatic idle-current reduction, self-test, overvoltage, under-voltage and over-current protection.

Features

High-performance, low price micro-step

Automatic idle-current reduction

Optical isolating signals I/O

Max response frequency up to 200Kpps

Low temperature rise, smooth motion

Online adaptive PID technology

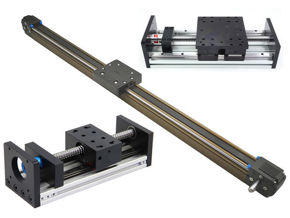

Applications

Suitable for a variety of large-scale automation equipments and instruments. For example: labeling machine, cutting machine, packaging machine, plotter, engraving machine, CNC machine tools and so on. It always performs well when applied for equipment which requires for low-vibration, low-noise, high-precision and

high-velocity.

Standstill Current Setting

SW4 is used for standstill current setting. OFF meaning that the standstill current is half of the dynamic current; and ON meaning that standstill current is the same as the selected dynamic current. Usually the SW4 is set to OFF, in order to reduce the heat of the motor and driver.

Driver functions descriptions

Driver function | Operating instructions |

Output

current

setting | Users can set the driver output current by SW1-SW3 three switches.

The setting of the specific output current, please refer to the instructions of the driver panel figure. |

Microstep setting | Users can set the driver Microstep by the SW5-SW8 four switches. The setting of the specific Microstep subdivision, please refer to the instructions of the driver panel figure. |

Automatic half

current function | Users can set the driver half flow function by SW4. "OFF" indicates the quiescent current is set to half of the dynamic current, that is to say, 0.5 seconds after the cessation of the pulse, current reduce to about half automatically. "ON" indicates the quiescent current and the dynamic current are the same. User can set SW4 to "OFF", in order to reduce motor and driver heating and improve reliability. |

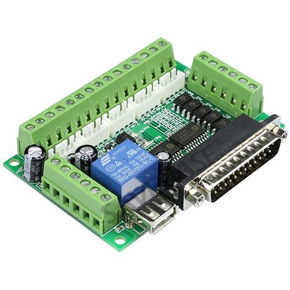

Signal interfaces | PUL+ and PUL- are the positive and negative side of control pulse signal; DIR+ and DIR- are the positive and negative side of direction signal; ENA+ and ENA- are the positive and negative side of enable signal. |

Motor interfaces | A+ and A- are connected to a phase winding of motor; B+ and B- are connected to another phase winding of motor. If you need to backward, one of the phase windings can be reversed. |

Power interfaces | Recommended operating voltage is 24VDC-80VDC or 20VAC-60VAC. |

Indicator lights | There are two indicator lights. Power indicator is green. When the driver power on, the green light will always be lit. Fault indicator is red, when there is over-voltage or over-current fault, the red light will always be lit; after the driver fault is cleared, if re-power the red light will be off. |

Installation

instructions | Driver dimensions:150×98×51mm, please refer to dimensions diagram. Please leave 10CM space for heat dissipation. During installation, it should be close to the metal cabinet for heat dissipation. |

Control signal and external interface:

Signal amplitudes | External current limiting resistor R |

5V | Without R |

12V | 680Ω |

24V | 1.8KΩ |